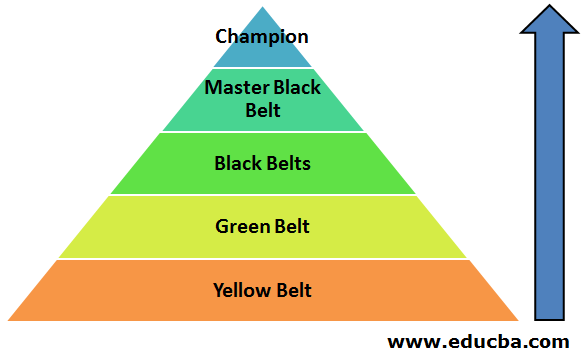

Professionals with the intermediate green belt certification can manage small to mid-level projects but typically don’t lead major ones. At the other end of the spectrum are master black belts who have demonstrated proficiency in every aspect of the Six Sigma framework. Naturally, beginners hold the rank of white or yellow belt. The Six Sigma certifications are divided into the following belts: The progressive belt system preserves the integrity of the Six Sigma framework while helping businesses implement the methodology more effectively.

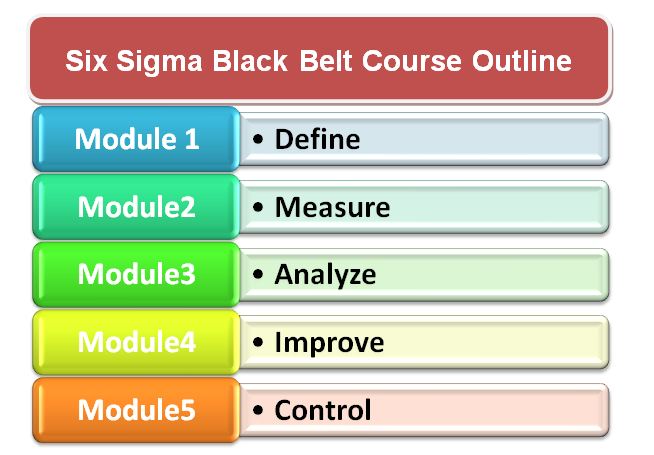

To obtain a new Six Sigma belt level, you must demonstrate that you’ve acquired the skills consistent with that ranking. Think of each course as a prerequisite for the next belt. The Six Sigma certification framework is progressive, meaning you can’t immediately enroll in an advanced course unless you’ve obtained the belt that precedes it. Six Sigma uses a belt ranking system similar to that of karate and other martial arts. Ultimately, such a culture can reduce errors at your workplace and deliver a better customer experience. It can be adapted to meet the needs of businesses both inside and outside the manufacturing space.ĭespite these subtle differences, both methodologies can help your organization create a problem-solving culture. This makes Lean Six Sigma particularly appealing to manufacturers, especially if they’re already using other Lean management concepts.Īlternatively, Six Sigma is designed to minimize process variability and prevent product defects.

While both of these terms refer to process improvement and optimization, Lean Six Sigma differs in that it also focuses on using resources efficiently to create as little waste as possible. When used strategically, Six Sigma can help you improve not just operational processes but overall business outcomes as well. A “six sigma” is six standard deviations from the closest specified threshold.Īs applied to manufacturing, increasing the number of deviations between process limits - minimum quality standards for example - will decrease the likelihood of product defects. The methodology takes its name from a sigma, which is one standard deviation of measurement. Government entities, healthcare companies, and many other types of businesses now use Six Sigma for process optimization. Although Six Sigma was originally designed for manufacturing, it’s been adopted by organizations across a wide range of industries. The original Six Sigma framework was developed in the 1980s by Motorola. Six Sigma is a process optimization methodology - an approach to quality improvement that equips teams with concepts and strategies to refine business processes, reduce errors, and boost productivity.

#Six sigma belts meaning how to#

How to get started with Six Sigma today.After reading, you’ll have deeper knowledge of what Six Sigma is and the different belt levels that are part of the certification process. This article will provide an overview of what each belt signifies and how the certification process relates to Six Sigma’s process optimization methodology. Learning more about the different belt levels can help you decide whether or not the Six Sigma certification process is right for your organization. Six Sigma uses belts - like in karate - with different colors designating different skill levels. People who want to develop their skills in Six Sigma and benefit from its teachings can pursue certifications. Six Sigma is a methodology for improving processes within businesses. But even if you’re familiar with this organizational framework, you might not fully understand Six Sigma certification and what the different belt levels mean. Maybe you work at a company that uses it. If you’re a project manager or a business leader in the manufacturing industry, you’ve probably heard of Six Sigma. Learn about Six Sigma belt levels and what they mean

0 kommentar(er)

0 kommentar(er)